Varnish in Compressors

Varnish deposits are an almost universal problem in the industrial sector

For turbines and compressors

Extend

oil life

Prevent

downtime

Maximize system

efficiency

Why varnish is a hidden threat to compressor system reliability

Varnish deposits lead to filter plugging, bearing wear, valve failures, and carbon buildup

Over time, varnish accumulation can result in frequent shutdowns, emergency repairs, and costly disruptions to operations

Annual losses can be significant and depending on application can run into the millions

The Texaco VARTECH ISC advantage – for compressors

| In-operation system cleaning – add VARTECH® Industrial System Cleaner directly before an oil change, minimizing downtime |

|

| Effectively dissolves and disperses significant amounts of varnish – even from cooler or stagnant oil areas | |

| Prevents re-adhesion –

cleaner breaks down varnish

into fine particles that don’t

re-stick or clog filters |

|

| Proven in field tests – real-world compressor cases show significant varnish removal and system

recovery within 2–3 days |

Texaco VARTECH ISC

Varnish removal results demonstrating VARTECH industrial system cleaner effectiveness

Day 1, before adding

VARTECH® Industrial System Cleaner

Oil filter

Filter housing

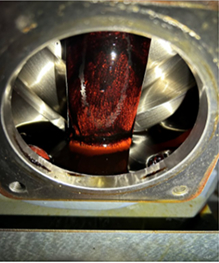

Compressor element with varnish and little old oil remaining

Day 4, 2nd 45 minute cleaning cycle

Clean oil filter

Clean filter housing

Clean compressor element with varnish and some old oil remaining

Trusted varnish removal results across Europe

Rotary Compressor, GA37VSD+:

system cleaned in 3 days

Discuss with Texaco Lubricants representatives to find out how VARTECH can help.