Texaco VARTECH Industrial System Cleaner

High performance industrial system cleaner offers advanced varnish removal in turbines and compressors

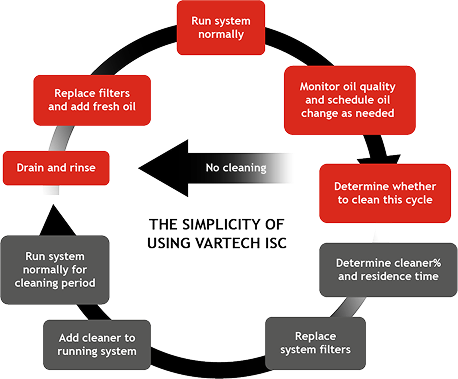

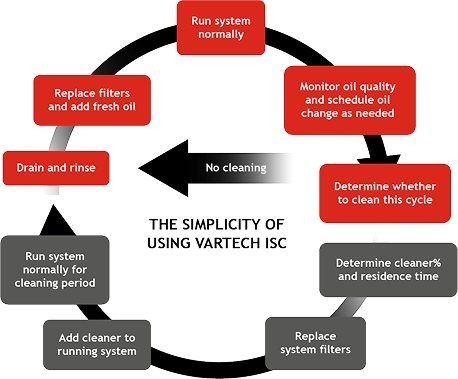

Texaco VARTECH Industrial System Cleaner (ISC) is a non-solvent-based product that can be added directly to oil during operation, designed to clean varnish and sludge from lubricating systems in steam and combustion turbines before a scheduled oil change.

In testing, VARTECH industrial turbine cleaner outperforms many other commonly used cleaners in cleaning efficiency, effectiveness, and system compatibility without significantly affecting water separability and oxidation stability.

VARTECH Industrial System Cleaner

Premium performance industrial varnish

removal product that can be added directly

to oil in use during operation, helping to

reduce downtime.

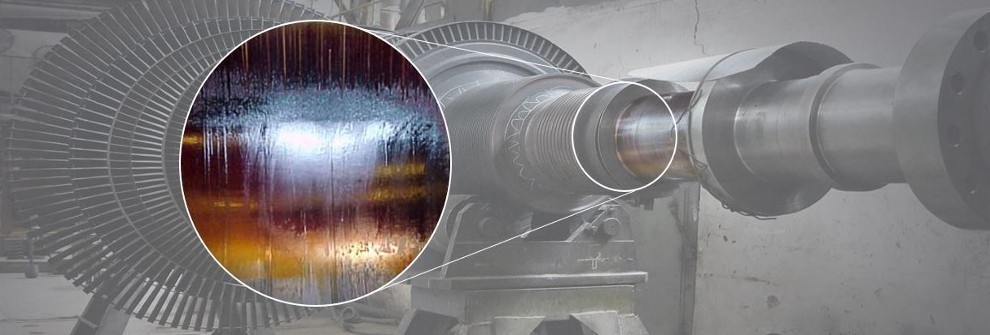

Cleaning varnish in turbine applications

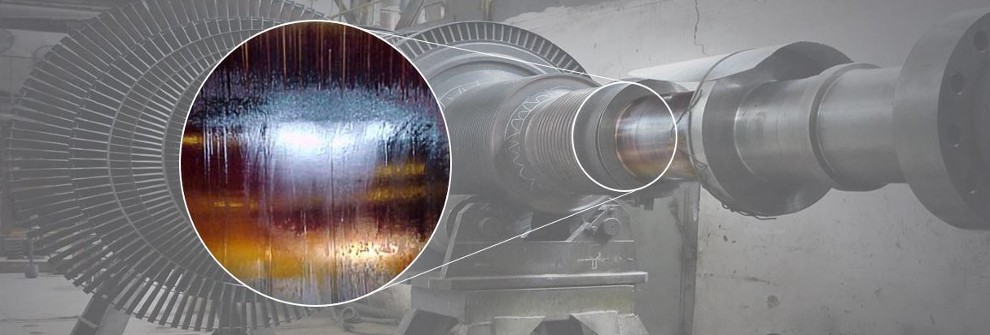

Cleaning varnish in compressor applications

What is varnish in industrial systems?

A lubricating oil degrades when it undergoes thermal and mechanical stress, creating varnish precursors that, over time, form layers of varnish.

Once formed, varnish is a thin, oil-insoluble deposit composed primarily of organic residue, mixed with metals, inorganic salts, and other contaminants.

How do I know I have a varnish problem?

Symptoms of varnish deposits vary even between identical systems. Typical symptoms include sticky servo or thermostatic valves, sticking hydraulic cylinders, inefficient oil coolers leading to high oil temperatures, high bearing temperatures, and subsynchronous vibration in high-speed bearings and seals.

Why clean varnish from your industrial system?

Varnish buildup reduces a lubricant’s heat transfer properties and causes your system to run hotter and hotter. The consequences won’t just threaten your equipment - they’ll hit you on your bottom line. It can lead to de-rated equipment, unplanned shutdowns, inefficient operation, meaning increased maintenance labour, management and spending, and higher costs and lost profits for the business owner.

VARTECH customer success stories

Texaco VARTECH helps restore SJV Gas Turbine to maximum productivity for an annual revenue gain of over $350,000*

Texaco VARTECH industrial system cleaner helps restore gas turbines, saving $80K+ In annual maintenance costs *

Texaco VARTECH industrial system cleaner helps bring the temperature of a compressor system down from >110°C to around 105°C*

Texaco VARTECH helps outlet bearing temperature decrease from over 100°C to around 93°C within four days*

*actual savings can vary

Benefits of VARTECH® Industrial System Cleaner:

Industrial system cleaning:

Compatible with many in-service oils at recommended concentrations (5–20% by volume), with minimal impact on oil viscosity (53 cSt, suitable for ISO 32–68 oils). Causes minimal filter plugging and preserves lubricant water separability.

Industrial system cleaning performance:

Demonstrated superior varnish deposit removal in extensive lab and field testing. Designed to dissolve internal varnish deposits and stabilise them for effective removal with used oil.

System-Friendly Formulation:

Exhibits very good seal compatibility and minimal impact on long-term new oil performance, even with residual levels up to 2%.

VARTECH FAQs

For most cleaners, the duration for effective cleaning is usually from 1 to 30 days. The longest VARTECH Industrial System Cleaner has been tested in a system is five months.

Cleaners are designed to move varnish deposits from surfaces into the lubricant. Oil with these suspended contaminants is not as good a lubricant as fresh oil without them. It is best practice to change the oil once the cleaner has done its job.

Modern lubricants consist of high-performing advanced technology. Since cleaners were not an original part of the oil formulation, long-term performance is hard to predict. Consideration should therefore be given to the likely actual long-term effect on lubricant performance by the cleaner remaining in the system.

Some alternative cleaners can plug filters, although this depends on varnish and oil chemistry, the type of deposits, and the configuration of the system. It is good practice to have spare filters on hand during cleaning.

Filter differential pressure may increase during cleaning depending on the amount and characteristics of the varnish moved from surfaces into the oil, as larger removed varnish pieces can lodge in the filter increasing pressure. Hard particles (if present) previously stuck in the sticky varnish will also be caught by the filter increasing differential pressure.

VARTECH Industrial System Cleaner has been extensively tested in the field with occasional mild increases in filter differential pressure, but never exceeded alarm limits, even in equipment where other cleaners have done so repeatedly.

Removing every speck of varnish is unlikely. The varnish chemistry will vary throughout the system. Some chemistries like soft varnish in coolers and sludge in reservoir bottoms often clean quickly and completely. Hard, polymerized deposits or those containing contaminants can be very stubborn and may remain after cleaning.

Areas with low flow or low temperatures are unlikely to be completely cleaned, although a good cleaner will soften the varnish to ease manual removal.

Versatile lubricants with VARTECH technology: GST Advantage

GST Advantage RO is a high-performance industrial gas and steam turbine oil, suitable for use in gas and steam turbines where extreme temperatures are experienced and where oils with robust thermal and oxidative stability are required.

Useful articles

Defeat destructive varnish to optimise performance

Interested in Texaco VARTECH Industrial System Cleaner?