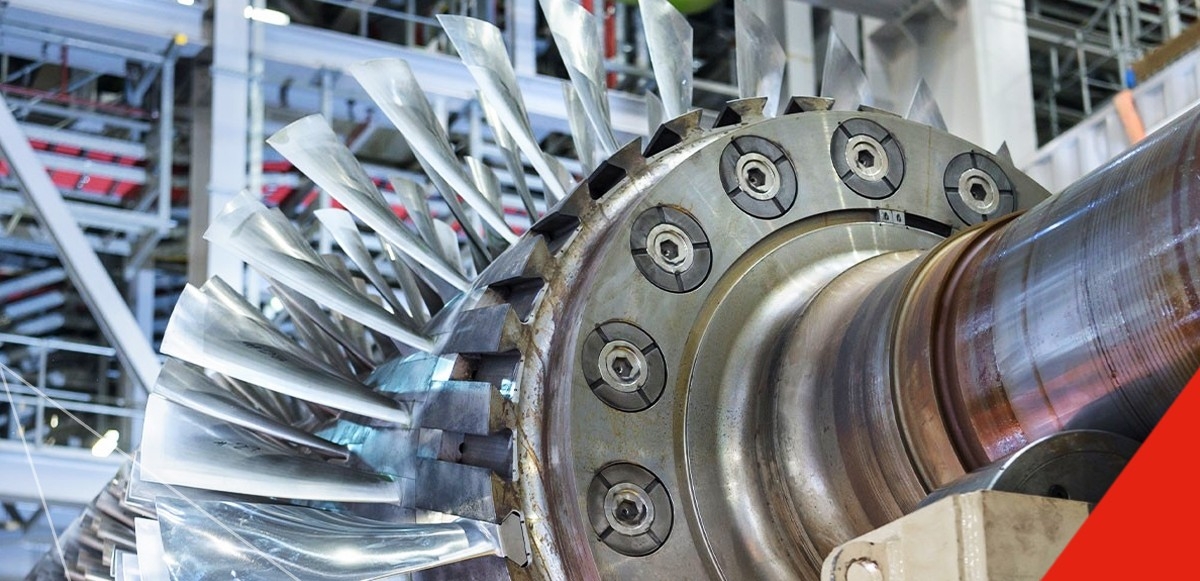

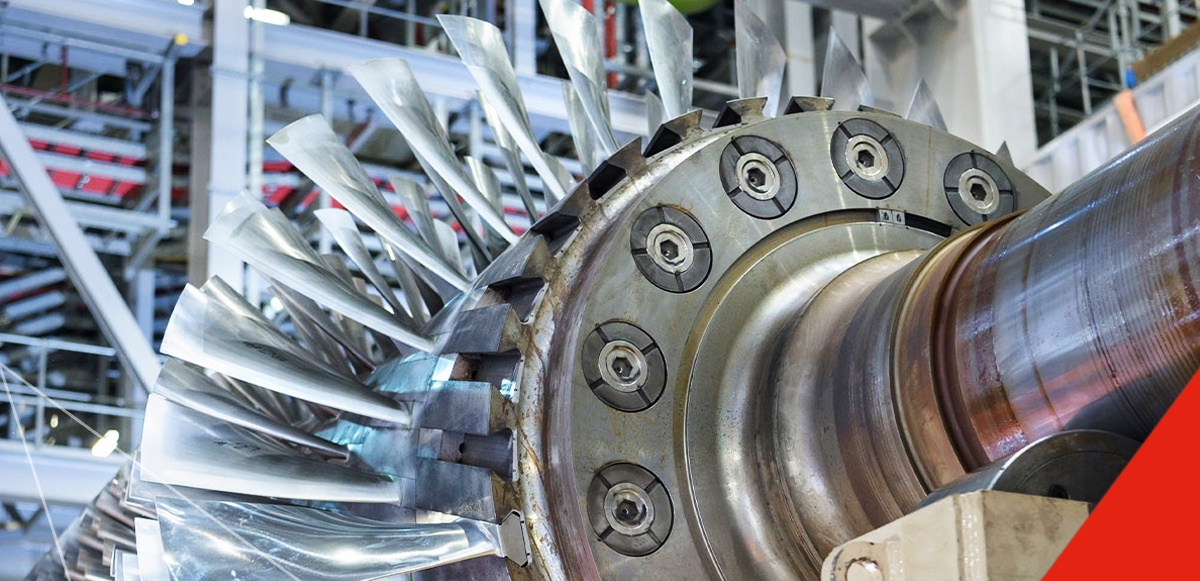

VARTECH Industrial System Cleaner:

Clearing the Way for Industrial Reliability

In the world of industrial plants, a silent threat often lurks within critical machinery: varnish. This residue can quietly build up, leading to reduced efficiency, increased maintenance and costly downtime. To better understand this issue and how to help combat it, we turned to the specialists. In this in-depth interview, Texaco’s technology experts provide comprehensive answers on VARTECH Industrial System Cleaner (ISC), detailing its introduction, how it differs from traditional methods and the tangible benefits it can bring to operators seeking greater efficiency and peace of mind.

How long has VARTECH ISC been available and who is the target audience for the product?

VARTECH ISC has been available across much of Europe since 2022. The product is aimed primarily at operators of large industrial plants, such as in the energy sector, but also at municipal utilities, chemical companies, or manufacturers with their own power and compressed air generation. A key criterion is that the larger the oil volume and the longer the oil drain intervals, the greater the benefit. This is especially true in turbines or large compressor systems that are in use for ten years or more without an oil change; varnish build-up can cause serious problems, with potentially large follow-on costs.

What makes VARTECH ISC technology different than other solutions on the market?

VARTECH ISC technology is fundamentally different due to its “clean-and-control” approach. Traditional solutions focus on cleaning during shutdown, either during planned maintenance or when problems are already acute. VARTECH ISC, however, is added to the oil circuit several weeks before the planned oil change. This gently dissolves existing deposits while the system remains in operation. The second step involves the use of specially formulated lubricants with VARTECH ISC technology, which helps to ensure that the formation of new varnish is significantly reduced. It’s a sustainable solution that combines both cleaning and prevention in one system.

How exactly does the industrial cleaning process work in practice?

The cleaning process begins with careful analysis. First, we assess the oil quality and the degree of varnish contamination. Once the timing is determined – typically a few weeks before a planned oil change – the VARTECH ISC is added to the existing lubricant while the system remains in operation. The cleaner acts chemically on the deposits, breaking them down into microscopically small particles that do not redeposit but are removed with the used oil. After the oil change, our GST Advantage turbine oils or Cetus compressor oils are used, which contain special additives that significantly slow the formation of varnish. This all requires minimal effort for the operator but has a major effect on system cleanliness and operational reliability.

What specific problems does varnish cause – and why is it dangerous?

Varnish is essentially a residue that forms as oil degrades, comparable to a thin, sticky layer that builds up on critical components. This is particularly problematic in areas like valves, bearings, or heat exchangers. These layers act as insulation, impair heat dissipation, reduce lubrication performance, and can block valves. In extreme cases, this can lead to unplanned shutdowns, overheating, or even failure of safety systems. The consequences are not just high repair costs, but often also production losses with massive economic impacts. That’s why it’s so important to take action early.

What kind of support do you offer in terms of oil monitoring?

The Texaco LubeWatch program offers oil analysis to provide insight into oil quality throughout the entire service life. This allows varnish precursors or other critical values to be detected early. This is an important factor in preventing problems, especially in high-performance systems. LubeWatch is optional, but we highly recommend it, as it provides an excellent data foundation for preventive maintenance strategies.

Are there success stories from international applications?

Absolutely. VARTECH ISC has proven its worth, particularly in regions with extreme conditions, such as desert environments or offshore platforms. In these conditions, large power packs often operate under high pressure, high temperatures, and with limited maintenance infrastructure. That’s where VARTECH’s reliability really stands out. We’ve also seen strong results with municipal utilities and industrial steam turbines across Europe, such as reduced bearing temperatures, lower vibration levels, and improved system efficiency.

How long does the application of the VARTECH ISC solution take?

The duration depends greatly on the size and condition of the system. Typically, the cleaning phase is between four to eight weeks. In particularly stressed systems, such as those with long oil service lives or poor oil quality, it can take a bit longer. The key factors are the correct dosage of the system cleaner and continuous monitoring of oil parameters. Using operational data and laboratory analysis, we can precisely determine the optimal time for the oil change.

Would VARTECH ISC be useful in hydraulic systems as a possible area of application?

Hydraulic systems, for example, in plastics processing or injection moulding, are often heavily affected by varnish. The issue is that many operators consider deposits to be “normal” because they don’t know any different. That’s exactly where Texaco VARTECH ISC can step in. Initial field tests have shown that VARTECH ISC also works well in these systems, not only as a cleaner but also as a preventive measure.

Why is VARTECH ISC not just a “booster” like other products?

A booster suggests a quick, short-term effect. VARTECH ISC works to remove the root cause and protect against recurrence. The cleaner’s chemical action is based on the targeted breakdown of varnish deposits into microfine particles that won’t clog the system. After that, premium lubricants specially formulated to help prevent the formation of new deposits are used. So VARTECH ISC is not a quick fix, it’s a well-founded, long-term solution to a structural problem.

What should a potential customer look for as typical warning signs of varnish?

Classic symptoms of varnish include a rise in bearing temperatures, filters needing to be replaced more frequently, or valves no longer operating reliably. An unexplained increase in energy consumption or declining system efficiency can also be warning signs. In such cases, it’s worth taking a closer look as it’s often more cost-effective to act early than to face expensive mechanical cleaning or even unplanned downtime later on. Our recommendation is to contact Texaco experts at the first signs of uncertainty. We’ll work together with the customer to assess whether VARTECH ISC can help.

How does cooperation with OEMs and maintenance firms work?

Collaboration varies greatly depending on the operator and system type. Maintenance providers with framework agreements are often involved and, in such cases, Texaco coordinates closely with all parties, including OEMs (original equipment manufacturers). When there are technical queries, we’re in direct contact with the OEM. In many cases, our solution ends up being recommended by maintenance firms or OEMs.

Are there limits to using VARTECH ISC, or situations where you would advise against it?

There are certainly systems where mechanical cleaning is unavoidable – for example, when varnish deposits are so severe that they impede flow or affect safety-critical components. In such cases, VARTECH ISC can still be helpful, as a preparatory step or in combination with mechanical cleaning. We evaluate each system individually and give an honest recommendation. If we feel that VARTECH ISC isn’t the right solution, we say so.

Where is VARTECH ISC technology heading? Are there already new fields of application?

Working together with colleagues in the US and Asia, Texaco experts are continuously observing global trends and user experiences. These insights flow directly into product development. In addition to hydraulic systems, Texaco, as part of the Chevron family of brands, is currently testing applications in gearboxes/gear units and complex compressor systems. Our goal is to help wherever oil is used long-term, supplies critical components, and varnish causes problems.