Mitigating varnish build-up in power generation turbines

You know the old adage, “an ounce of prevention is worth a pound of cure?” Many power generation companies we work with are spending huge amounts of money and labour fixing problems caused by varnish build-up in their gas turbines. The good news is there are now lubrication solutions available to help prevent or at least mitigate varnish from forming in the first place.

Power generation companies are often contractually obligated to deliver a certain amount of power over a certain amount of time. Currently they are facing multiple simultaneous challenges: the reduction in the use of coal, the reduction in the use of nuclear power and the increased use of renewable energy sources such as solar and wind energy, which are not always available on demand. They also have to be ready to activate peaking units instantly when demand spikes.

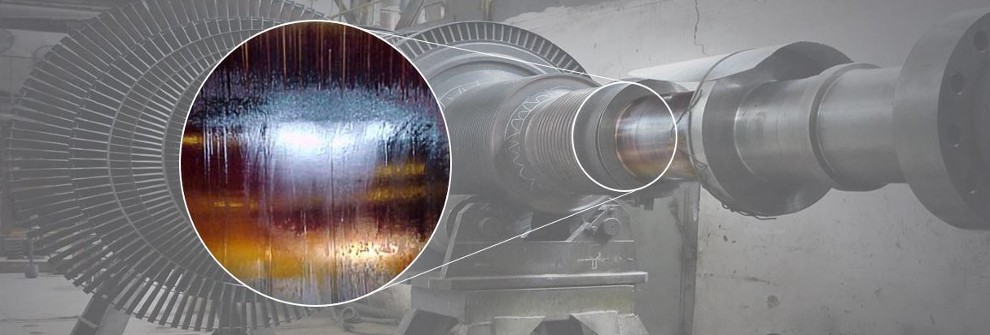

Varnish created by lubricant oxidation in a turbine can cause gas regulation valves to stick and impair oil cooler performance, resulting either in serious operational issues or, worst case-scenario, in an automatic shutdown or failure to start. An inability to deliver power on demand can result in severe fines and penalties, combined with enormous maintenance and repair bills, not to mention lasting damage to the provider’s reputation.

Not surprisingly, varnish resistance has garnered a lot of interest in the turbine world. Historically, varnish issues arose from lubricants using Group I base oil stock, which is prone to oxidation under high-temperature operating conditions. Now, some turbine OEMs have decided to get ahead of the problem. They have issued specifications for lubrication producers to come up with turbine oils that are more resistant to both oxidation and to the deposits that result from oxidation, which can ultimately cause varnish to form.

Chevron has recently launched its next generation GST Advantage™ turbine oils with VARTECH® Technology. Texaco GST Advantage turbine oils with VARTECH Technology are specifically formulated to meet these more stringent OEM requirements. Texaco GST Advantage EP and GST Advantage RO turbine oils are formulated with Group II base oils (which are more refined than Group I base oils, and exhibit comparatively improved oxidation stability) together with an additive system that is designed to further reduce the tendency for varnish precursors to form. By limiting the varnish precursors, these Texaco GST Advantage turbine oils help control varnish formation and extend oil life. In dry turbine oil stability testing, or “TOST”, our GST Advantage Turbine oils exhibited very good oxidation and deposit control performance, as well as varnish resistance.

Some operators in the industry have chosen to use polyalkylene glycol or PAG-based turbine oils, some of which are purported to be “varnish free.” Our testing has concluded that that claim is not always true. PAG oils are hydroscopic, which means they will absorb water and experience some acid formation and degradation as a result.

Importantly, Chevron is now able to provide the power generation and petrochemical industries with a new alternative to help control varnish build-up and to reduce the risk of varnish-related turbine failure, in turn avoiding the heavy costs of turbine maintenance and repair after the fact.

Chevron has developed a holistic two-step approach to help control varnish. The VARTECH solution starts with our VARTECH Industrial System Cleaner, added near the end of the in-service oil’s life to help clean existing varnish while the equipment remains online. The second step of the VARTECH holistic solution is designed to control varnish. Filling the newly cleaned systems with selected Texaco GST® Advantage turbine oils help to improve oxidation stability, reduce oil degradation, and extend oil life by limiting harmful varnish precursors that can lead to varnish formation.

To learn more about our Texaco GST Advantage turbine oils, click here.